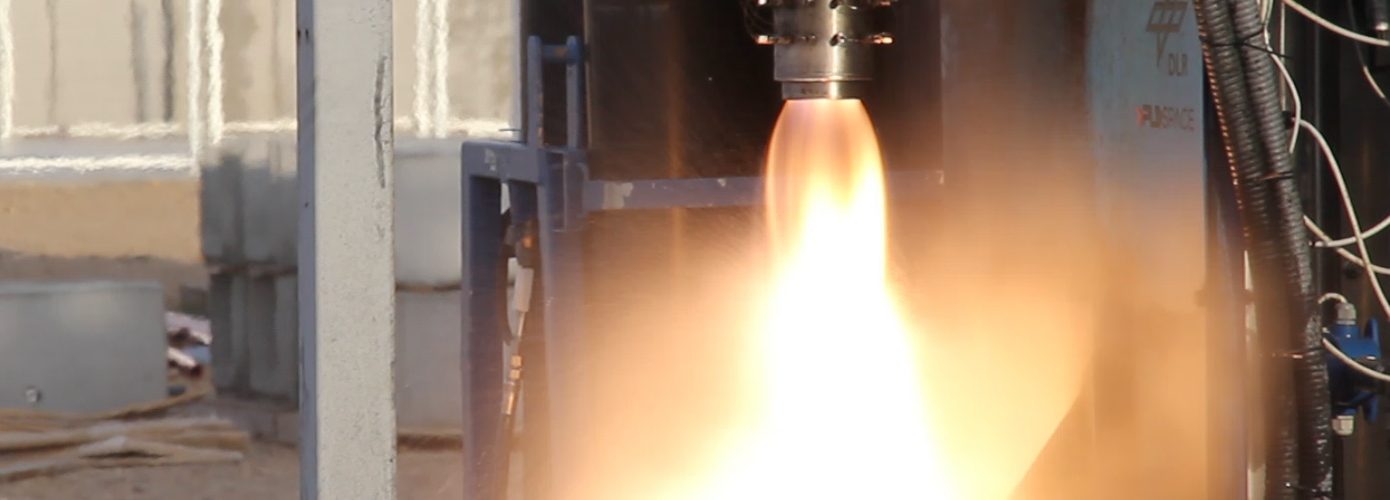

In hot firing tests in September 2018, a research team led by DLR subjected a reusable rocket engine to an initial test run. It successfully completed a total of 18 tests at the high-pressure test bench of Spanish project partner PLD Space, with a firing time of up to 45 seconds, thereby showing very high combustion efficiency of over 90 percent. Liquid oxygen (LOx) and kerosene were used in the tests.

The rocket engine, developed by DLR scientists specifically for this application, consists of two central components – the metal injector head and the ceramic combustion chamber. Belgian project partner 3D Systems manufactured the prototype injector out of a nickel-chromium alloy using metal 3D printing. The researchers used a special high-performance material for the combustion chamber – a carbon fibre-reinforced ceramic that consists mainly of silicon carbide was developed primarily at the DLR institute in Stuttgart.

Related links